The Hidden Cost of Aggregate in Load Support Applications

From laying the foundation for roadways to structuring parking lots and laydown yards, aggregate has been the backbone of construction projects around the globe. However, its omnipresence shouldn't overshadow the considerable expenses associated with its use, which stem from direct procurement, application costs, and other hidden factors.

The Contractor's Guide to Cost-Effective Base Course Construction

As a contractor, you're always looking for ways to optimize your construction projects, ensuring you deliver high-quality results while staying within budget. Base course construction is critical to any transportation infrastructure project, and finding cost-effective solutions is essential for your success. In this guide, we will explore the challenges of base course construction and introduce you to a revolutionary product that can help you reduce costs and improve efficiency.

The Key to Soft Soil Construction: Unlocking the Value of the Dynamic Cone Penetration Test

Traditional road construction often overlooks the crucial step of understanding soil conditions, leading to unnecessary expenses and compromised durability. Our approach centers on the dynamic cone penetration test (DCP), a game-changer in designing cost-effective, long-lasting roads on soft soil. Download our free resource to identify how our expertise in conducting on-site DCP tests and interpreting their results ensures you invest wisely, reducing upfront material costs and future maintenance expenses.

Your Ultimate Guide to Tensar InterAx geogrids

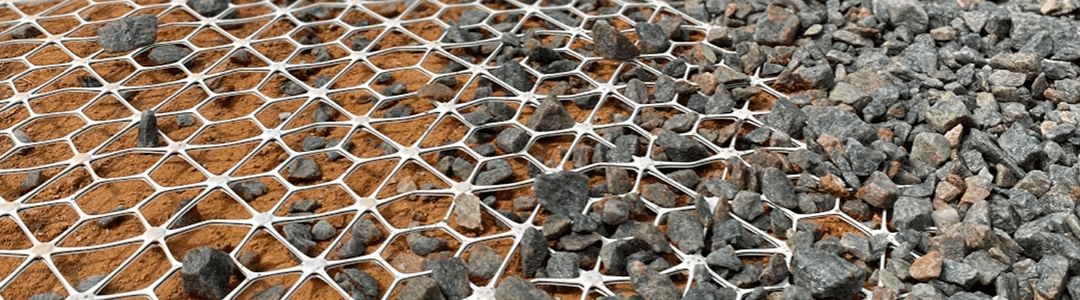

Engineers and Contractors often experience stress over completing their projects due to soft soil, which requires them to purchase more aggregate and material or, worse, extend their timelines, leaving them at risk of penalties and fines. At GeoSolutions, we have partnered with Tensar to provide you with InterAx geogrid, Tensar's most innovative technology to save you time, reduce cost, and improve the lifetime value of your sitework projects.

A Cost Analysis on Concrete Paving and Rip Rap for Slope and Channel Stabilization Projects

In civil engineering and construction, slope and channel stabilization are essential for preventing soil erosion, managing waterways, and ensuring project integrity. Techniques such as Concrete Slope and Channel Paving, Concrete Rip Rap, and Stone Rip Rap are popular for their effectiveness, yet they vary significantly in cost implications, impacting project budgets and outcomes. This article delves into the cost considerations of using these methods for stabilizing slopes and channels, offering in-depth analysis and insights to guide the selection of techniques, including alternative methods, for slope and channel stabilization initiatives.

Applications for Successful Erosion Control of Slopes and Channels

Soil erosion, which often leads to the failure of slopes and channels, occurs over varying periods, from days to decades, a process that conventional designs and construction practices frequently fail to address adequately. This oversight results in structures, slopes, and channels that are susceptible to failure. To combat this, it is crucial to identify both soft and hard armor solutions that can effectively control erosion, thereby ensuring the longevity and stability of slopes and channels while also protecting the environment.

Channel Design Essentials: A Guide to Understanding N-Values

Discover how understanding and optimizing N-Values can revolutionize your approach to water flow management, reduce construction and maintenance costs, and minimize environmental impact. Learn about Manning’s formula, innovative solutions like HydroTurf and Turf Reinforcement Mats, and how to choose the right hard and soft armor solutions for your project.

Fabric Formed Concrete, Ultimate Guide

Fabric Form Concrete is revolutionizing civil engineering and architectural design with its novel approach to concrete molding. Using flexible, textile-based forms allows for the creation of structures that boast organic, fluid shapes, combining aesthetic appeal with structural integrity. This article delves into its applications, benefits, installation processes, and the overall value it adds to modern construction. Aimed at architects, engineers, and curious enthusiasts alike, we explore how fabric-formed concrete transforms our built environment and paves the way for more sustainable and innovative construction practices.

Gabions, Your Ultimate Guide

Gabions serve as a versatile, reliable, and cost-efficient solution for reinforcing slopes, stabilizing channels, or enhancing landscapes, offering significant long-term value and effective management of environmental challenges. These structures, widely used in both engineering and landscaping, are essentially baskets or mattresses filled with rocks and encased in a durable wire mesh. This design provides critical support and stabilization, making gabions an adaptable choice for a variety of applications.

GreenArmor System, Your Ultimate Guide

The GreenArmor System merges robust engineering with ecological sensitivity, ingeniously blending the durability of hard armor solutions like concrete or rock with the aesthetic and environmental advantages of vegetative cover. This guide explores the GreenArmor System's unique components, including the innovative Futerra Turf Reinforcement Mats (TRMs), highlighting its numerous benefits. Designed for erosion control and environmental restoration, the GreenArmor System offers a synergistic approach by combining hard armor's strength with the lush appeal of vegetative cover. Its three-dimensional matrix core enhances this synergy, especially when integrated with high-performance, hydraulically applied mulches, making it a standout solution for sustainable construction and landscaping projects.

Articulated Concrete Blocks, Your Ultimate Guide

Articulated Concrete Blocks (ACBs) offer significant economic benefits due to their exceptional durability and low maintenance requirements, making them a financially prudent choice for erosion control. Especially effective in areas subjected to high-velocity water flow or intense wave action, ACBs play a crucial role in energy dissipation and soil protection. This erosion control system, utilizing concrete blocks designed to form a flexible, mat-like cover, safeguards vulnerable areas like riverbanks, shorelines, and slopes from erosion. The flexibility of ACBs, which can be hand-placed or interconnected by cables or geogrids, provides a reliable, sustainable solution to the challenges of erosion and environmental degradation.

Understanding the impact and benefit of Permeable Pavers

The urban environment is characterized by impervious surfaces, leading to environmental problems such as increased stormwater runoff and local flooding. In today's rapid urbanization, sustainable practices for infrastructure development have become more critical than ever due to the growing concern for the environment.

Your Ultimate Guide to the GEOPAVE Gravel Pavers

Porous pavements have become an essential tool in the sustainable infrastructure toolkit. They help to address stormwater management and groundwater recharge, reducing the environmental footprint of urban areas. Among the available solutions, the GEOPAVE Gravel Pavers stand out as an innovative option designed to handle daily traffic and deliver ecological and cost benefits that exceed conventional choices such as porous asphalt and pervious concrete.

Your Ultimate Guide to the GEOBLOCK® Grass Paver System

In the quest for sustainable infrastructure, the GEOBLOCK® Grass Paver System emerges as a beacon of innovation, reshaping our understanding of turf protection. Imagine a system that not only offers unparalleled strength to support hefty traffic loads but also champions the environment at every step.

Understanding the Cost of Chemically Treated Subgrades Using Lime and Cement

One often-discussed topic in civil engineering is using chemical treatments for subgrade stabilization - specifically, the application of Chemical Stabilization by mixing on-site materials with Lime and Cement. These materials have proven effective in enhancing the load-bearing capacity of subgrades, thus preventing road failures and providing a sturdy foundation for construction and pavements. While the technical merits are well-documented, the discussion on the cost implications of these treatments is often less comprehensive. This blog post aims to bridge that gap by presenting a detailed overview of the costs of using Lime and Cement for Chemical Subgrade Stabilization.

How Tensar® InterAx® Geogrid is Revolutionizing the Subgrade Stabilization Industry

For engineers and contractors like yourselves, safety, cost and time savings, and your project's success are non-negotiable. Yet when soft soils threaten that very commitment, most individuals default to costly and time-consuming conventional methods such as lime and cement-treated soils for their subgrade stabilization needs. In our blog post "How the Tensar InterAx Geogrid is Revolutionizing the Subgrade Stabilization Industry," we take a moment to explore how Tensar’s InterAx geogrids can help you shorten your construction schedules, reduce material costs, and enhance the lifetime value of your surfaces.

How to use Tensar® InterAx® Geogrids For Subgrade Stabilization

When it comes to soft soils, improving their strength, stability, and load-bearing capacity is critical. Tensar InterAx greogrid's optimized geometry improves the geogrid-aggregate layer's performance by resisting the aggregate's radial displacement under load. Its unique open aperture shapes yield a broader range of sizes and open areas, allowing better compatibility with a more comprehensive range of aggregate qualities and gradations.

Breaking down the costs of conventional building materials for sitework construction.

For generations, we've relied on Topsoil & Compost Manufactured Topsoil, Aggregate, Concrete Paving & Rip Rap, Lime & Cement Treatment, and Asphalt. However, with the continuous increase in material prices and the growing emphasis on cost-efficiency, innovation, and sustainability, it becomes crucial to reassess the significant costs associated with these conventional resources. Today our industry stands at a crossroads, an intersection where habit meets progress. In our latest blog post, we dive into the financial realities surrounding these materials. It's time to reassess, reevaluate and revolutionize your approach.

Topsoil is Expensive: Identifying Cost Saving Alternatives for Engineers and Contractors

Often we are confronted with the paradox of topsoil. While it's an essential part of our work in revegetation, the cost of this precious resource can prove prohibitive. Numerous factors contribute to topsoil's high price tag, from extraction to transportation and amending efforts.

Yet, cost-effective alternatives exist, promising both financial and environmental savings. This blog post aims to provide an overview of the financial realities surrounding topsoil and compost-manufactured topsoil.

ProGanics: A Cost-Effective, Sustainable Alternative to Topsoil & Compost Manufactured Topsoil

In our pursuit to determine the most cost-effective and sustainable alternatives to topsoil and compost-manufactured topsoil (CMT), one product stands out as a leading solution, ProGanics. ProGanics provides an abundant source of organic matter and soil-building components to quickly modify soil chemistry and initiate growth establishment and buildup of the uppermost "O" and "A" soil horizons, meaning you need much less topsoil or compost to get the job done right, with most projects requiring no additional topsoil or compost. READ in our blog post "ProGanics: A Cost-Effective, Sustainable Alternative to Topsoil & Compost Manufactured Topsoil."

Slope Vegetation & Erosion Control with ProGanics

Erosion control and vegetation establishment on side slopes are crucial aspects of many civil engineering and construction projects. However, achieving successful vegetation growth on side slopes can be challenging, given the inherent difficulties of these areas, including steep inclines, erosion risks, and often poor soil quality. ProGanics proves to be an efficient and effective solution. Unlike traditional topsoil, which presents safety and installation challenges on slopes and tends to wash away before vegetation is established, ProGanics adheres well to slopes and provides a stable growing medium while ensuring effective erosion control. READ.

Ultimate Guide to Watershed Geo HydroTurf®

Are you looking for an effective solution to combat erosion in high-risk areas such as construction sites, slopes, and waterways? Look no further than HydroTurf®. This advanced erosion control product offers superior protection, combining the environmental and aesthetic benefits of vegetation with the performance and maintenance benefits of hard armor. To READ about the benefits of HydroTurf®, read our blog. Our experts provide valuable insights and information on how to effectively implement erosion control solutions to protect your project's structural integrity and ensure long-term success. Don't wait, read our blog today and take the first step in overcoming erosion control challenges.

Effective Strategies for Erosion Control: Protecting Your Soil, Water, and Landscapes

Erosion control plays a vital role in land management as it helps preserve the integrity of soil, water, and landscapes by mitigating erosion's negative impacts. There are various physical, chemical, and biological methods to combat erosion effectively. Identify the benefits of each to select the most effective erosion control strategy for you.

Install Guide for Channel Lining Using Concrete Canvas

Looking for a durable and cost-effective installation process for your channel lining projects? Download our free installation guide to identify how Concrete Canvas is installed 10-times faster than traditional concrete lining methods.

2781 Glen Garden Drive

Identify how we were able to revitalize a bar ditch that will support significant channel flow from the top of the slope, while providing the city of Fort Worth with a long term solution they can replicate on future drainage projects to reduce costs related to installation, materials, time, and maintenance.

Concrete Canvas vs. Reinforced Concrete for Channel Applications

Traditional reinforced concrete is too expensive, requires too much labor, and is susceptible to corrosion. Download our free Concrete Canvas vs. Reinforced Concrete for Channel Applications to learn how much you could save on your next channel project.

Your Ultimate Guide to Concrete Canvas

Don't let soil erosion and water penetration lead to the collapse of your erosion control installation projects. Improve the stability and lifetime value of your channel and ditch projects using Concrete Canvas. Concrete Canvas® is a flexible, composite, concrete-filled geosynthetic that hardens on hydration to form a thin, durable, and waterproof concrete layer. Identifying how your projects can benefit from using Concrete Canvas.

Revegetation Project's Five Most Common Points of Failure

Download our free PDF and learn about the five most common points of failure regarding your revegetation projects and the solutions available to overcome them.

UPRR Big Spring Slope Protection

Identify how we stabilized and revegetated a steep slope/embankment where soils washed into ballast/train tracks due to erosion and sheet flow.

Ultimate Guide for Soil Restoration using ProGanics DUAL

Soil restoration is a critical factor in the success of revegetation projects. When soils become depleted and devoid of vital sustenance and microbiology, no amount of fertilizer will overcome the soil deficiencies. One of the main ways to ensure the success of your revegetation projects is by adequately restoring the soil before beginning the project. Soil restoration includes adding vital nutrients and organic matter lost due to neglect, construction, and overuse. Learn how you can ensure quick results and the long-term success of your revegetation projects with proper soil restoration on your job sites.

Texas Common Seeding Guide for Vegetated Retaining Walls

The "Texas Common Seeding Guide for Vegetated Retaining Walls" will help you select suitable native grass to ensure proper filtration and the long-term success of your vegetated retaining walls.

Building Vegetated Retaining Walls with GEOWEB® System

If you're looking for an environmentally friendly and cost-effective alternative to conventional retaining walls and MSE walls, the GEOWEB® System is an industry-leading solution. The naturally vegetated structure creates a sustainable living environment while meeting all structural design requirements with no need for complicated installation processes and materials that can be costly and time-consuming.

Case Study: Eagles Canyon Raceway

Identify how this Mirafi H2Ri solution eliminated the need to install a more expensive and invasive groundwater drainage system. Providing a cost-effective solution for subgrade reinforcement and water management of ongoing groundwater seepage.

Cost Comparison Card: Fuel Cost Savings with Mirafi H2Ri

The high cost of gas is a major concern for many business leaders, and finding ways to save on fuel is a top priority. Download our free "Cost Comparison Card: Fuel Cost Savings with Mirafi H2Ri" to identify how you can save up to $13,000.00 on your fuel costs by including the Mirafi H2Ri in your next project.

Your Ultimate Guide to Mirafi H2Ri

Our roadways and other civil structures are constantly under attack from moisture causing premature deterioration in both paved and unpaved applications. This leads to costly maintenance, or worse, complete reconstruction. Using Mirafi H2Ri in roadway designs can help to reduce the moisture content in moisture-sensitive soils throughout the life of the structure. In this blog post, you will learn why Mirafi® H2Ri is the ultimate integrated geosynthetic for subgrade stabilization in environments with moisture-sensitive soils, including expansive soils.

Case Study: SH105 Grimes County

The project team eliminated the need to cement stabilize the subgrade and installed a geosynthetic reinforced pavement with Mirafi H2Ri, a high strength, moisture-management geotextile, without adding any additional thickness to the original section, which included 7” of flex base and 8” of asphalt.

Waterproofing & Reflective Cracking Mitigation with Asphalt Interlayers

Over time, as pavements age and are subject to heavy traffic loads and extreme weather conditions, pavement distress begins to accumulate. This distress can include potholes, rutting, and cracking, requiring the need for maintenance or rehabilitation to prevent premature pavement failure. However, the existing cracks are one of the biggest threats to the future performance of the pavement, in that they become reflective cracks, which quickly propagate upward through a new asphalt overlay, leading to a rapid loss of serviceability of the newly surfaced pavement. This blog post will explore how to waterproof and mitigate reflective cracking using asphalt pavement interlayers.

Reference Guide: How H2Ri Equalizes Moisture Beneath Pavements

Expansive soils can lead to extensive cracking in pavements and costly maintenance. Download our reference guide, "How H2Ri Equalizes Moisture Beneath Pavements” and learn how Mirafi H2Ri redistributes and equalizes moisture to mitigate reflective cracking and extend the performance of your pavement.

Asphalt Interlayer Applications & Product Selection Process

Designing pavements with longer lifespans at a lower cost can be difficult for engineers looking to deliver the best possible performance for every dollar invested. Unfortunately, high traffic loading, environmental conditions, and inadequate drainage constantly challenge the functional lifespan of your pavements. Since 1965, the asphalt pavement interlayers have had an outstanding record of improving pavement performance while reducing maintenance and roadway life-cycle costs. This blog post will explore the various applications for asphalt interlayers and how to select the right interlayer for your pavement.

Case Study: Oates Road Container Yard Expansion

Identify how based on subgrade conditions and design parameters, Tensar InterAx NX850 reduced the overall thickness of the drive lane design by half, eliminating the need for chemically treating the subgrade. Ultimately, providing the client with a quick deploy option for any further drive lane expansions on site.

Solution Comparison: Tensar's InterAx Geogrids vs Conventional Methods

Don't let soft soils derail your projects or increase your budget. Download our PDF resource to identify how Tensar InterAx geogrid can reduce overall costs and installation time while improving your project's design life and performance.

Ultimate Guide to the Presto Geosystems GEOWEB® Geocells

As a trusted civil engineer, you can't afford to have your soil stabilization projects fail. Still, due to budget and time constraints, many civil engineers are forced to compromise the success of their projects. We don't believe you should have to stress over project failure. Identify how the Presto GEOWEB® Geocell’s straightforward design and easy implementation ensure long-term performance and your project's success.

What is a Turf Reinforcement Mat for Erosion Control?

Looking for a long-term, economical solution to erosion control by means of reinforced vegetation, Turf Reinforcement Mats are a great way to enhance your slopes and channels. TRMs or Turf Reinforcement Mats are easy to install, cost-effective, and work wonders on any soil or terrain.

What is an Erosion Control Blanket?

If you're looking for a cost-effective and environmentally friendly way to control soil erosion and protect your premature vegetation from rain runoff, look no further than Erosion Control Blankets. These versatile blankets are made from various biodegradable materials such as cotton, straw, wood, and coconut to determine their life expectancy and level of performance when protecting your site from potential erosion.

Tensar InterAx® Geogrid

Tensar InterAx Geogrid is the next generation in geogrid technology, and it’s made by one of the most trusted brands in the industry. This innovative product will provide you with cost-effective solutions for your project needs. Learn about how this game-changing solution can help improve your projects success!

Pavement Optimization with Geosynthetics

A poor subgrade is the number one cause of pavement failures. Even the best-designed and properly installed pavements can fail if the soil built upon is too soft and weak, resulting in structural issues. Understanding the importance of staying ahead of your pavement's natural life cycle is critical to avoid costly damage and time wasted. Learn how you can take control and reduce costs by as much as 20 percent.

What are geogrids?

By now, you have probably read or heard about the multiple benefits of using geogrids in various types of civil engineering construction applications. The two most significant are the improvement of your construction project's speed and the reduction of your overall cost. But you might still be asking yourself, what exactly are geogrids and how do they create an impact on my bottom line and project's success?

How geosynthetics can improve your next roadway stabilization project.

What if you didn't have to waste time, energy, and money trying to perform repairs and upgrades to your roadway stabilization projects after their completion due to early failure? What if, instead, you had the power to reduce cost and material by 20 to 40 percent, improve construction speed, and provide profitable solutions by saving on recurring expenses. Well, the truth is you can, with the use of geosynthetics.