Fabric Formed Concrete, Ultimate Guide

A construction technique reshaping the future of civil engineering and architectural design, Fabric Form Concrete stands out for its unique approach to concrete molding, utilizing flexible, textile-based forms to create structures with organic, fluid shapes that are as aesthetically pleasing as they are structurally sound.

Uncovering its applications, benefits, installation processes, and the overall value it brings to modern construction. Whether you're an architect, engineer, or just a curious enthusiast, join us as we uncover how fabric-formed concrete transforms our environment and lines the way for more sustainable and creative construction practices.

Fabric-formed concrete is a construction technique pouring concrete into flexible, textile-based forms to create unique, organic shapes.

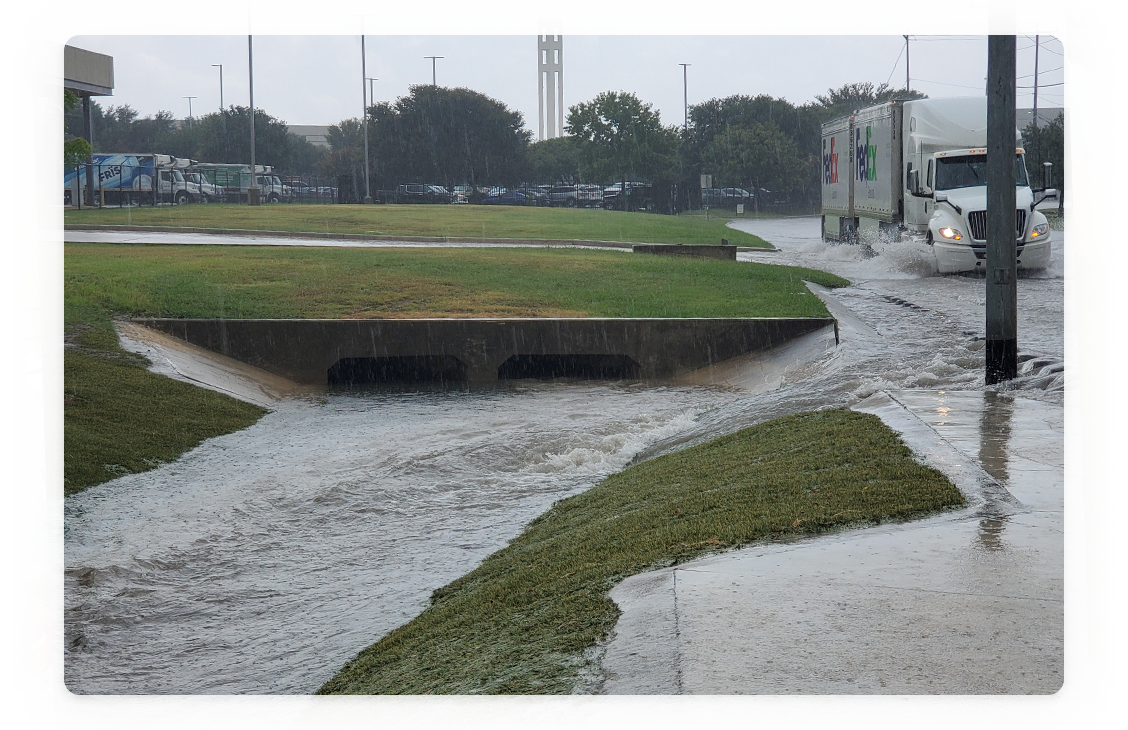

Protecting and lining slopes, channels, ditches, and pipelines using fabric-formed concrete is far-reaching. The flexibility of the fabric forms results in more efficient use of materials, potentially reducing the amount of concrete needed. This method offers aesthetic advantages and contributes to construction sustainability by promoting material efficiency and reducing waste.

The process of fabric-formed concrete involves using flexible textile molds instead of traditional rigid forms for shaping concrete. During construction, the fabric is stretched over a frame or a set of supports, creating a specific shape or contour desired for the concrete element. Once the fabric mold is in place, concrete is poured into it, and the fabric's flexibility allows the concrete to take on unique, organic shapes, with textures often influenced by the fabric's weave. As the concrete hardens, it retains the form given by the fabric, resulting in structural elements that have distinct shapes and surface patterns unattainable with traditional rigid forms. This method offers aesthetic and practical advantages, allowing for more creative and efficient use of concrete in architectural design.

Providing several key advantages, Fabric Formed Concrete offers unique aesthetic design flexibility and requires less concrete, delivering long-term performance at a reduced cost.

Fabric-formed concrete is particularly well-suited for applications that require a blend of structural integrity and aesthetic appeal. It is also ideal for environmentally conscious projects, as it promotes material efficiency and sustainability. In landscape architecture, fabric-formed concrete can create organic-looking hardscapes, water features, and terrain-like structures that blend seamlessly with natural surroundings.

Installing fabric-formed concrete involves a more specialized process than traditional concrete construction. It requires the design and preparation of unique fabric molds, which must be carefully crafted and supported to withstand the weight and fluidity of concrete. The process demands precise planning and execution, as the fabric's shape and tension significantly influence the final form and texture of the concrete. While this method provides greater design flexibility and aesthetic possibilities, it also introduces additional complexities in mold fabrication, setup, and concrete handling.

Like any concrete structure, maintenance of fabric-formed concrete involves regular cleaning, inspection, and occasional repairs. fabric-formed concrete does not inherently demand excessive maintenance. Regular upkeep is generally sufficient, similar to standard concrete structures, such as sealing to prevent water ingress and routine cleaning to maintain appearance. However, the specific context and use of the structure and the local environment can influence the maintenance needs of fabric-formed concrete elements.

The lifetime value of fabric-formed concrete is generally high, benefiting from the durability of concrete while offering unique aesthetic and sustainable advantages. The durability inherent in concrete constructions means these structures can last for decades with minimal maintenance, making them a cost-effective long-term choice. Additionally, the unique aesthetic qualities of fabric-formed concrete can enhance a building's or space's architectural value, potentially increasing its appeal and value over time. The method's material efficiency and potential for reduced environmental impact also contribute to its lifetime value, particularly in contexts where sustainable building practices are prioritized.

Using fabric-formed concrete for slopes and channels involves a series of steps that combine the unique properties of fabric-formed construction with the requirements of slope and channel shaping. Here's a step-by-step guide:

1: Design and Planning

A. Evaluate the slope or channel area for soil type, slope grade, and drainage patterns.

B. Plan the shape and size of the slope or channel. This includes determining the thickness and type of concrete based on structural needs.

C. Choose a suitable fabric material (like nylon or polyester) that can withstand the weight of the concrete and conform to the desired shape.

2. Preparing the Site

A. Clear and level the site as needed. For slopes, ensure stability to prevent landslides or erosion. Create Drainage Solutions: If necessary, install drainage systems to prevent water accumulation.

3. Constructing the Framework

A. Erect a framework of supports that will hold the fabric in place. This framework should mimic the final desired shape of the concrete structure.

B. Attach the Fabric: Stretch the fabric over the framework. It should be taut but have enough give to create the desired shapes.

4: Pouring the Concrete

A. Prepare a concrete mix suitable for the project requirements.

B. Carefully pour the concrete into the fabric form, starting from the bottom and working upwards.

C. Ensure even distribution to maintain the stability of the structure.

5: Curing and Finishing

A. Leave the concrete to cure. The time required can vary based on the concrete mix and environmental conditions.

B. Depending on the design, the fabric can either be left in place (if it contributes to the structural integrity) or removed once the concrete has hardened.

C. Apply any necessary finishes, such as sealants or protective coatings.

6: Inspection and Maintenance

A. Inspect the structure for any irregularities or weak points once the concrete is cured.

B. Plan regular maintenance checks, especially after extreme weather conditions, to ensure the structure's longevity.

7. Additional Considerations

A. Always follow safety protocols, especially when working on slopes.

B. Consider the project's environmental impact and take measures to minimize it.

C. Ensure that the project complies with local building codes and environmental regulations.