The Contractor's Guide to Cost-Effective Base Course Construction

As a contractor, you're always looking for ways to optimize your construction projects, ensuring you deliver high-quality results while staying within budget. Base course construction is critical to any transportation infrastructure project, and finding cost-effective solutions is essential for your success. In this guide, we will explore the challenges of base course construction and introduce you to a revolutionary product that can help you reduce costs and improve efficiency: InterAx Geogrid.

Base course construction is critical in developing transportation infrastructure projects like roads, highways, laydown yards, and airports. It refers to the initial construction layer placed on the subgrade, the naturally occurring soil layer that serves as the foundation for the pavement structure, infrastructure, or vehicular loads. It’s essentially the “middle” layer of a cross-section in paved applications. In unpaved applications, the base course makes up the main body of the cross-section, playing a critical role in the cost, quality, and life expectancy of your project.

1. Supporting the Pavement Structure:

The base course evenly distributes loads from traffic and other sources, preventing excessive stress on the subgrade and ensuring the structural integrity of the pavement system, infrastructure, or traffic loads.

2. Stabilization:

The base course helps to minimize the impact of subgrade irregularities, such as settlement and moisture fluctuations, by providing a consistent and stable platform for load support.

3. Reducing Maintenance Costs:

A properly constructed base course can minimize the need for costly repairs and maintenance over the lifespan of the transportation infrastructure project.

Transportation infrastructure projects utilize various materials for base course construction, depending on local availability, project requirements, and budget constraints. Some of the most common materials include:

Crushed Gravel:

Like crushed stone, crushed gravel offers good stability and drainage but may have slightly inferior load-bearing capacity.

Crushed Slag:

A byproduct of the steel industry, crushed slag can be used as a base course material, providing an environmentally friendly alternative to traditional aggregate materials.

Recycled Asphalt Pavement (RAP):

RAP is a cost-effective and sustainable option for base course construction, made from reclaimed asphalt materials that have been processed and crushed for reuse.

Geogrids:

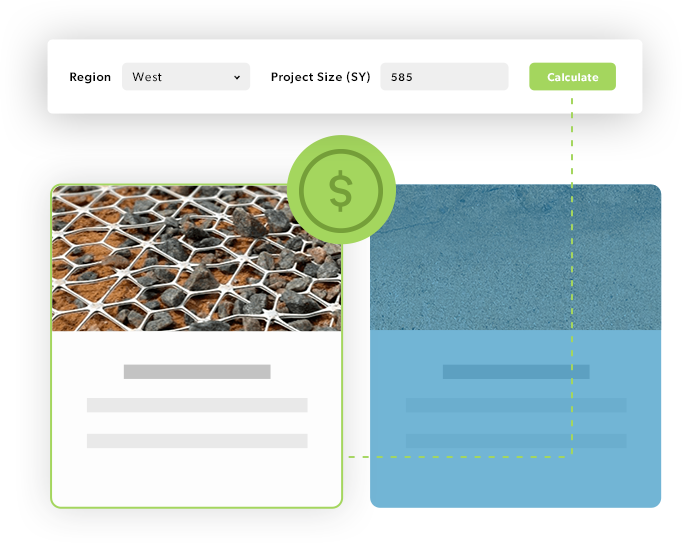

Geosynthetic technologies like InterAx Geogrid can be incorporated into the base course to enhance stability, reduce material usage, and lower costs. It is typically placed between the subgrade and base course to interact with the base material to create a mechanically stabilized layer, offering a high-performance and proven approach to site construction.

Base course construction projects are subject to various cost factors, including fluctuating raw material prices, transportation and logistics, labor costs, regulatory compliance, and equipment costs. Raw material prices, such as aggregate, cement, and asphalt, can be volatile and influenced by market forces, supply chain disruptions, and geopolitical events, increasing base course construction costs. The cost of transporting these materials to the project site can significantly contribute to the overall project budget, particularly if materials need to be sourced from distant locations.

Strict environmental regulations and permitting requirements can add to the cost and complexity of base course construction projects, particularly when managing and disposing waste materials. Lastly, the cost of owning or renting the necessary equipment for base course construction, such as excavators, loaders, and compactors, can be substantial and may increase due to inflation and technological advancements.

The escalating construction materials, labor, and equipment costs significantly impact contractors and construction project budgets. These rising costs lead to reduced profit margins for contractors, making it increasingly difficult to run a sustainable and competitive business in the face of financial pressures. Additionally, such increases often result in budget overruns, which can delay projects, necessitate renegotiations, and spark disputes among contractors, engineers, and project owners. This environment challenges contractors' ability to submit competitive bids, thus affecting their competitiveness in securing new projects. Moreover, to mitigate these financial pressures, some contractors might compromise on quality, potentially endangering their infrastructure projects' long-term durability and safety. This multifaceted impact highlights the pressing need for strategies to manage rising costs and maintain quality in construction projects. Discover the real costs of aggregate on your projects and their impact on your bottom line in our latest blog post. READ MORE

InterAx Geogrid is a revolutionary product that can help contractors optimize their base course construction projects. It offers a cost-effective and efficient solution to the challenges outlined above. When properly designed, InterAx Geogrid enhances the performance of base course materials by offering a stiff layer, known as a mechanically stabilized layer (MSL). This MSL allows the base material to interact with the apertures and geometric strength of the geogrid to reduce lateral movement of the material under loads while maximizing compaction.

Benefits of Using InterAx Geogrid in Base Course Construction

Reduced Material Usage

InterAx Geogrid can significantly reduce the base course material required for a project, as it helps distribute loads more efficiently and stabilize the subgrade. Reducing material usage can lead to lower costs and a more sustainable construction process.

Improved Construction Speed and Efficiency

InterAx Geogrid can help speed up construction time and improve overall project efficiency by reducing the required thickness of base course layers. This can lead to reduced labor costs, shorter project timelines, and increased contractor competitiveness.

Enhanced Pavement Performance and Longevity

InterAx Geogrid has been proven to improve the performance and longevity of pavement systems, reducing the need for costly repairs and maintenance over time. This can lead to long-term cost savings for project owners and improved safety and reliability for users of the transportation infrastructure.

Cost-Effective Alternative to Traditional Base Course Materials

InterAx Geogrid can be a more cost-effective alternative to traditional base course materials, such as crushed stone or gravel, especially when considering the total project cost, including material, transportation, labor, and equipment expenses.

Base course construction is a critical aspect of transportation infrastructure projects, and finding cost-effective solutions is essential for contractors looking to optimize their projects and maintain profitability. InterAx Geogrid offers a revolutionary approach to base course construction, providing a cost-effective, efficient, and sustainable solution that can help reduce costs, improve efficiency, and enhance the performance and longevity of pavement systems. By incorporating InterAx Geogrid into their base course construction projects, contractors can better navigate the challenges of rising construction costs, ensuring the successful delivery of high-quality transportation infrastructure projects.

Due to the storage yard’s drainage plan, areas beneath stacked containers would hold moisture for long periods of time after rain events. This subgrade saturation caused certain areas to become inaccessible until the soils dried out. Identify how Tensar InterAx NX850 reduced the overall thickness of the drive lane design by half, eliminating the need for chemically treating the subgrade, providing the client with a quick deploy option for any further drive lane expansions on site.