How to use Tensar® InterAx® Geogrids For Subgrade Stabilization

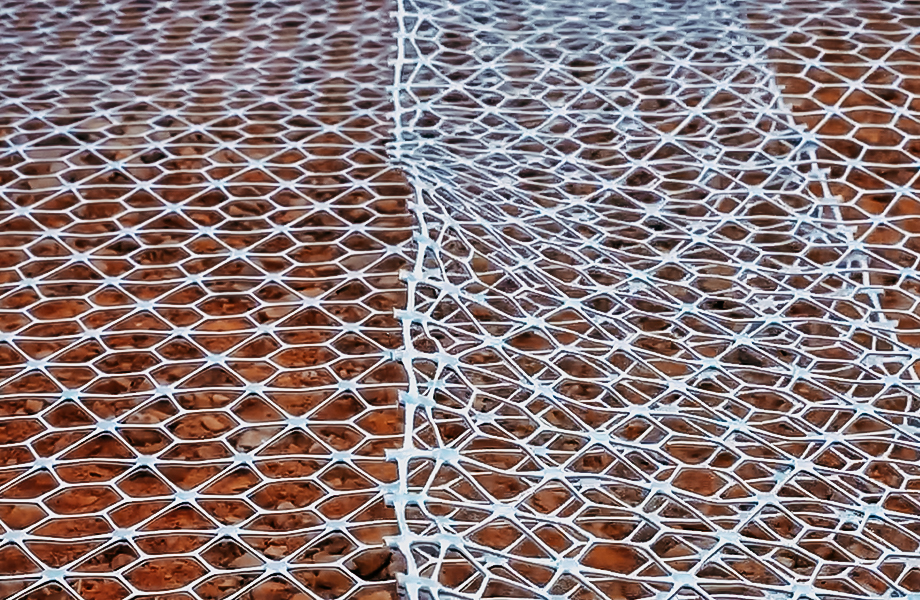

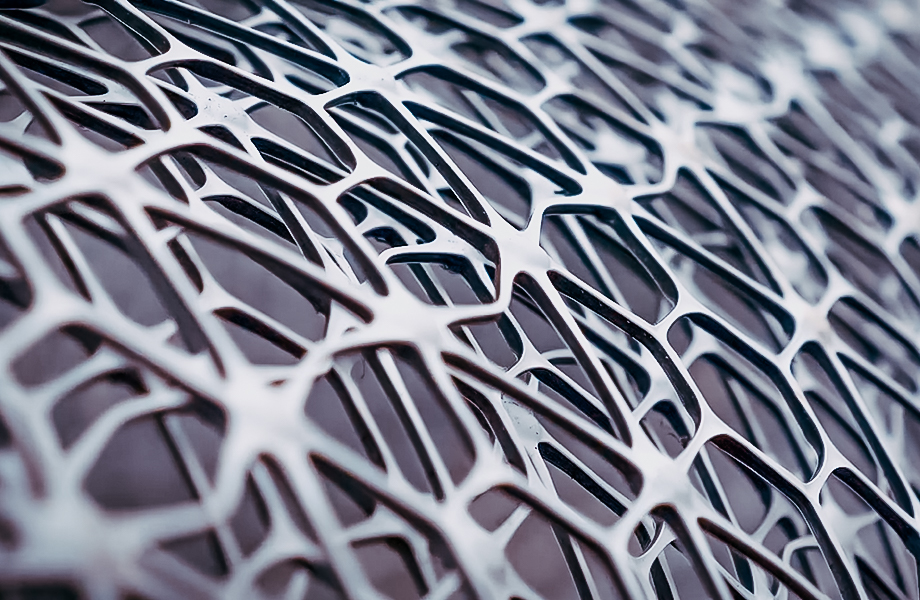

When it comes to soft soils, improving their strength, stability, and load-bearing capacity is critical. Tensar

InterAx greogrid's optimized geometry improves the geogrid-aggregate layer's performance by resisting the

aggregate's radial displacement under load. Its unique open aperture shapes yield a broader range of sizes and

open areas, allowing better compatibility with a more comprehensive range of aggregate qualities and gradations.

Better performance means less aggregate is required to meet project requirements, saving costs, time, and carbon

emissions. This blog post will discuss how to install Tensar's InterAx geogrids helping you create more

resilient, longer-lasting surfaces for your subgrade stabilization projects.

Begin by clearing the site to the designed subgrade elevation and removing all unneeded topsoil, harmful debris, and unsuitable materials. Once cleared, level and compact the soil using the right equipment, ensuring the surface slopes slightly for adequate water drainage away from the construction area. Next, position the Tensar InterAx geogrid rolls on your chosen surface—the subgrade, subbase, or base elevation. Conveniently, Tensar InterAx requires no preliminary granular fill and can be laid directly on the subgrade. Simply cut the roll bands and spread the material over the prepared surface.

Lay out the geogrid so it aligns with the direction of traffic, ensuring it runs parallel to common travel patterns. For a seamless setup, shingle neighboring geogrid rolls in the direction you intend to spread the aggregate. Cut and overlap the geogrid when accommodating curves using sharp shears, a knife, or even a handheld power saw. Make precise cuts around manhole covers and other fixed obstacles. Should your project require a geotextile, place it down first, followed by the geogrid. For designs that call for a geotextile, ask about InterAx FilterGrid, which combines a 6 oz. geotextile heat bonded to the InterAx geogrid, allowing for single product installation.

To ensure the Tensar InterAx geogrid remains secure and maintains its alignment over the designated area, anchor it in place. Staking is optional and should be considered on a job-by-job basis. Begin by securing the start of the roll at its center and corners to the surface below; you can achieve this with small mounds of aggregate fill, pins with washers, or even large heavy-gauge staples, which can be driven through the grid's apertures into the subsoil. As you unroll the geogrid, straighten it out, ensuring you stretch out any wrinkles or slack by hand. Once laid, it's straightforward to adjust its position if required. Lifting from the edges to avoid tangles or snags when managing adjacent rolls.

Typically, an initial aggregate fill layer of 4 to 6 inches is recommended over Tensar InterAx geogrids. A more substantial fill might be necessary in exceptionally soft terrains to avert excessive rutting or bearing capacity issues in the subgrade soils below. You can dump aggregate fill onto the geogrid on solid subgrades (with CBR > 4). Conventional, highway-approved rubber-tired trucks, such as end dumps and belly dumps, can cautiously traverse the geogrid at slow speeds (under five mph), dispersing aggregate fill gradually. However, sudden stops and sharp turns should be avoided. Moreover, rubber-tired machinery should only operate directly on the geogrid if the underlying soil isn't susceptible to rutting during construction activities.

You can employ regular compaction techniques without dealing with exceptionally soft soils. In such scenarios, it's preferred to opt for static compaction over vibratory, especially when working with fine-grained, non-cohesive soils like silt. Once the aggregate fill is smoothly graded, compact it according to project guidelines before enduring sustained traffic. Failure to achieve proper compaction will lead to surface rutting when subjected to wheel loads, compromising the fill's adequate thickness and amplifying stress on the subgrade.

In conditions where the subgrade is saturated, opt for static compaction. Open-graded stone with a geotextile

beneath the geogrid or well-graded sand can benefit the primary bridging lift. However, these fill types might

require capping with a dense graded aggregate for paving or a proof roll pass.

Should deep rutting manifest beneath truck tires, resist the urge to grade these ruts. Such rutting is typically

a sign of overly thin, wet, or poorly compacted fill. By grading out the rut, you risk decreasing the aggregate

fill's thickness and exposing the geogrid. Address these ruts by filling them with the prescribed aggregate fill

and compacting. This not only rectifies the rut but might also deter future rutting. Always crown the fill

during grading to promote adequate drainage and keep the fill from becoming overly saturated.

In our journey to deliver superior and sustainable infrastructure solutions, understanding the nuances of Tensar

InterAx Geogrids becomes indispensable. Their unique design offers enhanced performance by effectively resisting

the radial displacement of aggregates under loads.

Improve the strength, stability, and load-bearing capacity of your subgrade.

Regarding soft soils, a consistent problem is the expensive cost of materials, labor, and equipment when using

conventional methods such as Lime and Cement for subgrade stabilization.

You deserve a cost-effective solution that you feel confident in. Backed by 30 years of research and validation,

the Tensar InterAx Geogrids are proven to be easier to install, reduce aggregate fill, and require no skilled

labor or specialized equipment, helping you save money and stay on track when unexpected soft soils jeopardize

the success of your projects.

Learn More