Navigating the High Cost of Asphalt

Asphalt's ubiquity in road construction, due to its unique properties, such as strength, durability, and versatility, has made it the long-preferred choice in roadway construction. However, amidst its advantageous properties, the associated costs raise significant concerns for engineers and contractors alike. This paper examines these costs and their implications to help pave the way toward more efficient planning and budget management for your roads.

Despite its beneficial properties and widespread use, the high cost of asphalt has become a significant concern for the industry. The expensive inputs and the intricacies of application can inflate the initial cost of asphalt-reliant projects. Additionally, the long-term maintenance costs of asphalt surfaces, resulting from weathering, oxidation, and traffic wear, can add substantial expenditure over the lifespan of the roadway.

Asphalt primarily consists of two components, the binder (bitumen) and aggregates, the ratio of which determines its characteristics and, in turn, its cost. Asphalt finds application in two primary layers of road construction - the surface/wearing course and the asphalt base course, each with different cost implications.

In roadway construction, the wearing course refers to the topmost layer of the road that comes into direct contact with traffic. It is the visible surface that drivers and pedestrians interact with on a daily basis. The wearing course is typically composed of asphalt concrete or other durable materials and is designed to provide a smooth, skid-resistant, and durable surface for vehicles.

The wearing course is located at the surface of the road and is responsible for bearing the brunt of traffic loads, including the weight of vehicles, the friction of tires, and the impact of weather conditions. It is directly exposed to factors such as vehicle braking, turning, acceleration, and weather elements like rain, snow, and temperature fluctuations.

The primary purpose of the wearing course is to provide a safe and comfortable riding experience for road users. It offers a smooth and even surface that allows vehicles to travel with minimal disruptions, ensuring driver comfort and reducing the potential for accidents. The wearing course also contributes to the overall safety of the road by providing skid resistance, which helps vehicles maintain traction and avoid skidding, particularly in wet or icy conditions.

Furthermore, the wearing course acts as a protective layer for the underlying pavement structure. It shields the lower layers, such as the asphalt base course and the aggregate base or subbase course, from the detrimental effects of traffic and environmental factors. It distributes the loads applied by vehicles over a larger area, reducing stress and preventing premature damage and deterioration to the underlying layers.

The wearing course also plays a crucial role in preserving the structural integrity of the road. It serves as a barrier against moisture infiltration, preventing water from seeping into the underlying layers, which can lead to weakened pavement and subbase materials. By protecting against moisture, the wearing course helps to extend the lifespan of the road and reduce the frequency of repairs or reconstruction.

Additionally, the wearing course contributes to the aesthetics of the road. It provides a visually appealing surface that enhances the overall appearance of the roadway and the surrounding environment. A well-maintained wearing course can create a positive impression, improve driver satisfaction, and contribute to the overall quality of the transportation infrastructure

The wearing course in roadway construction incurs costs related to material selection, construction, and maintenance. The wearing surface requires a high-quality asphalt mixture of finer aggregates and specialized binders. The quality and performance requirements of this mixture contribute to its higher cost. Construction costs include site preparation, surface preparation, asphalt mixture production, and placement. Additionally, regular maintenance activities like crack sealing, patching, and resurfacing are necessary to extend the life of the wearing course and minimize long-term costs. Proper maintenance helps to prevent the formation of potholes, cracks, and surface deterioration, which can lead to more extensive repairs or complete resurfacing.

The asphalt base course refers to the layer of asphalt that is situated between the wearing surface and the aggregate base or subbase course. It serves as a critical component of the road structure, providing support, stability, and durability to the overall pavement system. The asphalt base course is designed to withstand heavy loads and distribute them effectively to the underlying layers. It acts as a strong, load-bearing layer that helps to reduce stress and prevent deformation in the pavement structure. By transferring the applied loads over a larger area, it minimizes the potential for cracks, rutting, and other forms of distress that can occur due to traffic or environmental factors. The primary purpose of the asphalt base course is to enhance the structural integrity of the road. It helps to evenly distribute the weight of vehicles, including heavy trucks and buses, over a larger surface area. This reduces the pressure exerted on the underlying layers, such as the aggregate base or subbase course, thereby preventing excessive strain and potential failure. Additionally, the asphalt base course acts as a moisture barrier, preventing water infiltration into the underlying layers. Moisture can weaken the pavement structure by causing the subbase materials to lose their load-bearing capacity, leading to pavement failures like potholes and cracking. The impermeable nature of asphalt helps to protect the layers beneath and prolong the lifespan of the road. Furthermore, the asphalt base course provides a smooth and uniform surface for the wearing course, ensuring ride comfort and safety for road users. It serves as a transition layer between the wearing surface and the underlying layers, helping to distribute any irregularities in the subbase or aggregate base course, and providing a stable foundation for the final layer of asphalt.

The asphalt base course in roadway construction also involves associated costs. These costs typically include materials, construction, and quality control. The cost of materials for the asphalt base course depends on factors such as the type of asphalt mix (dense-graded or asphalt-treated base), aggregates used, and any stabilization additives. Construction costs include site preparation, grading, compaction, and placement of the base course. Quality control measures, such as testing and inspection, are essential to ensure that the base course meets specified requirements and performs as intended. Investing in quality materials and proper construction techniques for the asphalt base course can reduce long-term costs by minimizing the need for premature repairs or reconstruction due to structural failures.

While asphalt will continue to play a pivotal role in roadway construction, particularly for asphalt base courses, the industry is exploring innovative alternatives to reduce asphalt dependency and manage costs more effectively.

Here are a few common approaches:

Optimization of Layer Thickness: Conducting thorough pavement design and analysis can help optimize the thickness of each pavement layer. By accurately assessing traffic loads, soil conditions, and environmental factors, engineers can determine the appropriate thickness for the wearing course, asphalt base course, and other layers. This ensures that the pavement meets the required structural requirements while minimizing excess asphalt usage.

Use of Advanced Mix Designs: Utilizing advanced mix designs, such as stone matrix asphalt (SMA) or polymer-modified asphalt, can lead to improved performance characteristics. These mixes often provide enhanced durability, increased resistance to rutting and cracking, and reduced thickness requirements compared to traditional mixes. By selecting appropriate mix designs, it is possible to reduce the overall amount of asphalt material needed.

Recycling and Reuse: Incorporating recycled asphalt pavement (RAP) into new asphalt mixes can significantly reduce the amount of virgin asphalt required. RAP is obtained from milling or removing existing asphalt pavements and can be reprocessed and reused in new asphalt mixes. By using RAP, the demand for new asphalt material is reduced, making the project more environmentally friendly and cost-effective.

Pavement Preservation Techniques: Implementing pavement preservation techniques, such as crack sealing, chip sealing, or microsurfacing, can help extend the life of the existing pavement. These techniques can be applied to structurally sound pavements to address surface distresses and maintain their condition. By preserving existing pavement rather than completely removing and replacing it, the overall amount of asphalt required for the project can be reduced.

Alternative Materials: Exploring alternative materials, such as geosynthetics, can be considered for specific road sections or applications. Concrete pavements, for instance, may have different design requirements and thickness specifications compared to asphalt pavements, potentially reducing the amount of asphalt needed.

It's important to note that the reduction of asphalt quantity should always be balanced with the structural and performance requirements of the road, ensuring the longevity and safety of the pavement. Engineering expertise and adherence to local design standards and regulations are crucial in implementing these strategies effectively.

Finding new avenues to streamline processes and maximize value in an industry where efficiency is key is more than just smart business—it's an absolute necessity. Traditional construction methods often fail to deliver optimal performance, longevity, and cost-effectiveness. But what if a solution could address these issues, bolstering road durability while significantly cutting costs and construction time?

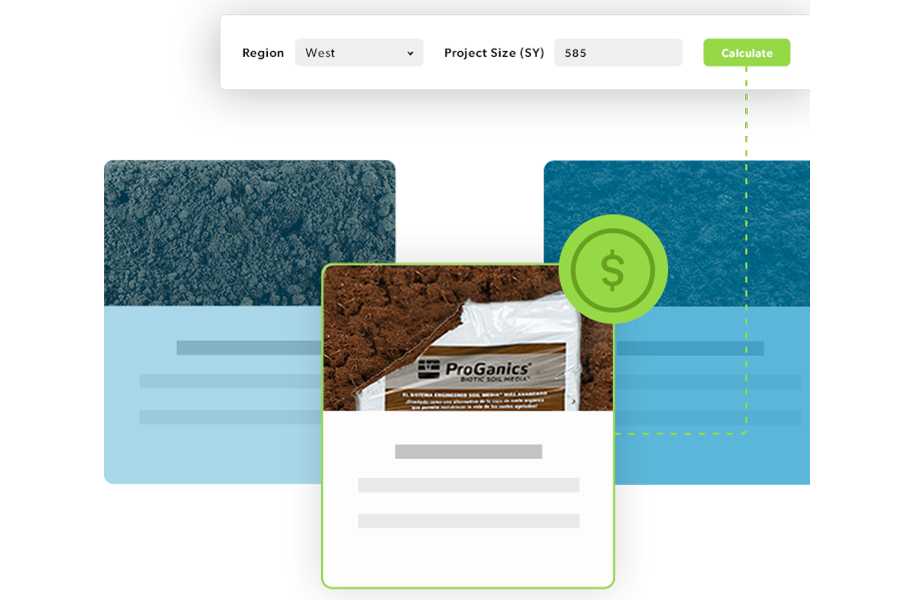

Harness the power of innovation to revolutionize your roadway construction projects by applying Asphalt Interlayers and Tensar's InterAx geogrid; the two acting as proven technologies for optimizing a roadway section, reducing budgets, and maximizing the life expectancy of the road. Interlayers ensure superior stability and fortify your roads against damaging reflective cracking. Tensar InterAx opens the door to established techniques in utilizing geosynthetics for subgrade stabilization and base course cost saving opportunities.

The future of roadway construction is now at your fingertips. Navigating the high cost of asphalt doesn't need to be a journey you take alone. With the technological advancements in geosynthetic interlayers and the revolutionary Tensar's InterAx technology, we can pave the way to more efficient planning, effective budget management, and vastly enhanced road performance.

Imagine cutting your asphalt layer's thickness by an impressive 30%, resulting in major savings. Envision accelerates your construction timelines and significantly reduces long-term maintenance and repair costs. Take the reins of your construction projects, steer your business towards innovation and efficiency, and chart a course toward a more sustainable and cost-effective future. Learn more about these industry-transforming technologies, and let us help you redefine the boundaries of what's possible in roadway construction. You have the power to change the way we build roads—embrace it.