Your Ultimate Guide to Tensar InterAx geogrids.

Engineers and Contractors often experience stress over completing their projects due to soft soil, which requires them to purchase more aggregate and material or, worse, extend their timelines, leaving them at risk of penalties and fines. At GeoSolutions, we have partnered with Tensar to provide you with InterAx geogrid, Tensar’s most innovative technology to save you time, reduce cost, and improve the lifetime value of your sitework projects.

Made for trafficked surfaces and foundations, Tensar InterAx geogrids minimize aggregate fill requirements, reduce or eliminate undercut, improve compaction, and extend service life. Ideal for subgrade stabilization, pavements, and working platforms, the optimized geometry of InterAx results in maximum granular fill confinement, resulting in improved compaction and movement restriction over time, enhancing performance and ensuring long-term stiffness.

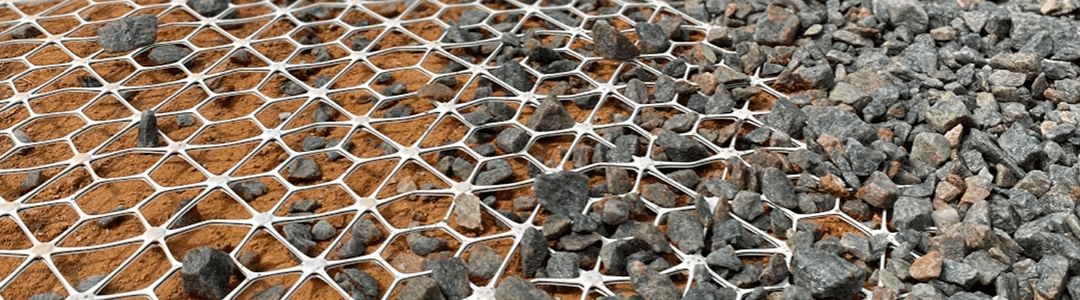

Tensar InterAx geogrid is manufactured from a coextruded, composite polymer sheet, which is then punched and oriented. The resulting structure consists of continuous and non-continuous ribs forming three aperture geometries (hexagon, trapezoid, and triangle) and an unimpeded suspended hexagon. The unique manufacturing process uses coextrusion to create a multi-layer product, giving InterAx the ability to accommodate aggregate nesting. The outer layers conform to the shape of the aggregate and hold it in place. Download Tensar's InterAx NX850 Product Data Sheet. Download Tensar's InterAx NX850 Product Data Sheet.

InterAx’s increased number of bearing surfaces provides improved performance of the geogrid-aggregate layer, by resisting radial displacement of the aggregate under load. InterAx’s 40% higher aspect ratio compared to conventional geogrids is proven to be more effective when interlocking and laterally restraining aggregate, while enhancing stiffness.

Three unique open aperture shapes yield a broader range of sizes and open area, allowing better compatibility with a wider range of aggregate qualities and gradations. Better performance means less aggregate is required to meet project requirements, saving costs, time, and carbon emissions.

Tensar InterAx incorporates innovations in both material science and geometry to provide exceptional performance and value across a wide range of materials and construction applications. Incorporating InterAx into a project creates the most efficient stabilized layer that retains stiffness over time to improve the performance of subgrades, pavements, haul roads, working platforms, and crane pads.

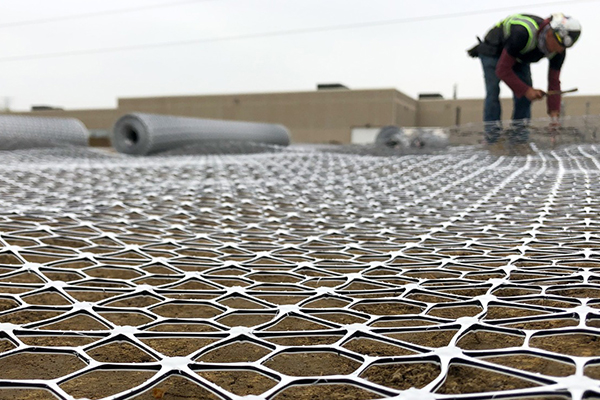

Like all Tensar stabilization geogrids, InterAx geogrids require no specialized equipment or expertise to install - just roll out the product, then place and compact aggregate or other granular material on it. As a result of its greater range and distribution of aperture shapes and sizes, Tensar's InterAx geogrid is designed to work well with a broad range of aggregates and granular materials. This gives you more flexibility in choosing the aggregate for your project, resulting in a straightforward installation process. Tensar InterAx geogrids can reduce overall aggregate requirements, materials, trucking, and carbon emissions. Watch or Download intstallation guide.

Almost every engineer and contractor has seen it before: you head to work, but you can’t get onto the site because of poor site conditions or wet weather. Equipment and manpower cost you time and money while you wait for the site to dry, or you over-excavate and import expensive fill. Maybe you try a layer of fabric, but if the soil is too soft, installation may be impossible. Solve your soft soils problem. Tensar InterAx geogrids are easy to install, reduce aggregate fill, and require no skilled labor or specialized equipment, allowing you to quickly get the job done on time and on budget. Plus, you get a more stable, longer-lasting solution compared to conventional methods.

Flexible pavement structures often fail prematurely because of progressive lateral and vertical displacement and a weakening of the aggregate base course. Tensar geogrid improves the overall stiffness of paved structures that support traffic by confining and interlocking with aggregate to create a mechanically stabilized layer (MSL). By decreasing aggregate fill requirements, additional truck deliveries are avoided, resulting in a more resilient solution with a smaller carbon footprint. From major highways to heavy-duty haul roads, Tensar's InterAx geogrid technology is proven to decrease material costs, increase pavement life, and reduce maintenance and rehabilitation.

Heavy-duty roads and surfaces commonly found in high-stress applications require special attention to pavement structural design and construction. They are constantly subject to extremely heavy wheel loads and must be designed to support large loads from truck traffic, cranes, and other cargo transfer equipment. These pavements serve a variety of critical markets, including intermodal, port and loading facilities, airport runways, warehouse/distribution centers, and heavy truck corridors.

The frequent heavy loads imposed on pavements of intermodal and warehouse/distribution centers already wreak havoc on maintenance budgets. Diminishing and costly aggregate supplies, tightening construction budgets, and heavier wheel loads have forced engineers, contractors, and owners to explore lower-cost alternatives to traditional methods of construction.

Tensar geogrids create a bridging effect over soft subgrades by locking aggregate particles more efficiently during compaction, stiffening the granular platform, reducing subgrade stress, and ensuring a more uniform surface even under the harshest conditions.

Operating cranes apply extremely high static loads to the subsoil where they are situated. The consequences of subgrade failure or excessive settlement can be catastrophic. In terms of the cost of equipment damage, lost time and potential injury to site staff. By including Tensar InterAx in your design, extensive cost savings can be attained, and in most cases, construction time can also be drastically reduced.

When unbound aggregate is placed on top of an InterAx geogrid, the coarser soil particles partially strike through the apertures and lock into position. This effect, commonly referred to as mechanical interlock, leads to lateral confinement of the unbound aggregate and a general stiffening of the layer. A stiffer, mechanically stabilized platform distributes load more efficiently onto the underlying soil, a critical improvement when the underlying subgrade is less than competent.

For a given aggregate thickness, adding Tensar InterAx geogrid results in an increased factor of safety against bearing failure and a reduction in vertical settlement. Alternatively, for a given target factor of safety, the thickness of the crane platform can typically be reduced by 50%.

Crane pads, laydown yards, storage facilities, and other working surfaces often support heavy, sustained loads. When poor subgrade soils are underneath these structures, the surface will quickly degrade beyond use if left untreated. Adding additional aggregate is a common yet very expensive solution that is only a short-term fix. A mechanically stabilized layer (MSL) using one or more layers of Tensar InterAx geogrid can easily support these heavy loads. Less aggregate is required, making the construction of these surfaces more affordable by reducing up-front costs. The MSL also improves site access and reduces future maintenance.

View the Oates Road Container Yard Expansion success story to identify how Tensar InterAx geogrid reduced the overall thickness of the drive lane design by half, and eliminated the need for chemically treating the subgrade. The drive lanes for the top lift equipment were stabilized, so that containers could be picked and stacked safely without compromising the integrity of the yard. GeoSolutions and Tensar provided the client with a quick deploy option using InterAx for any further drive lane expansions on site. In turn, helping them save time and money.

VIEW NOW

Twelve global teams and over 10,000 hours of research and development have led to the development of Tensar's InterAx geogrid, the highest-performing geogrid to date. Advanced material science improves compaction and restricts movement over time, retaining the stiffness long term and further enhancing performance. As an engineer or contractor, completing your sitework projects on time and within budget is critical for profitability, maintaining a positive reputation and securing future business.

Unfortunately, too often due to soft soils, you are forced to extend your project's timeline, or worse, increase your budget. This puts you and your team at risk for penalties or fees, and leaves you feeling stressed over the success of your project.

You don’t have to feel that way. At GeoSolutions, we believe you deserve a team of registered professionals, industry-leading innovators, and access to proven solutions to provide you and your clients the clarity and confidence you deserve.

This is why we have partnered with Tensar to provide you with their most innovative technology to save you time, reduce cost, and improve the lifetime value of your sitework projects.