How Tensar® InterAx® Geogrid is Revolutionizing the Subgrade Stabilization Industry

For engineers and contractors like yourselves, safety, cost and time savings, and your project's success are non-negotiable. Yet when soft soils threaten that very commitment, most individuals default to costly and time-consuming conventional methods such as lime and cement-treated soils for their subgrade stabilization needs.

Why? Despite a proven track record backed by 50 years of research and validation, most professionals are still unaware or uncertain of the power and dependability of Tensar InterAx geogrids for subgrade stabilization.

In our blog post "How the Tensar InterAx Geogrid is Revolutionizing the Subgrade Stabilization Industry," we take a moment to explore how Tensar’s InterAx geogrids can help you shorten your construction schedules, reduce material costs, and enhance the lifetime value of your surfaces.

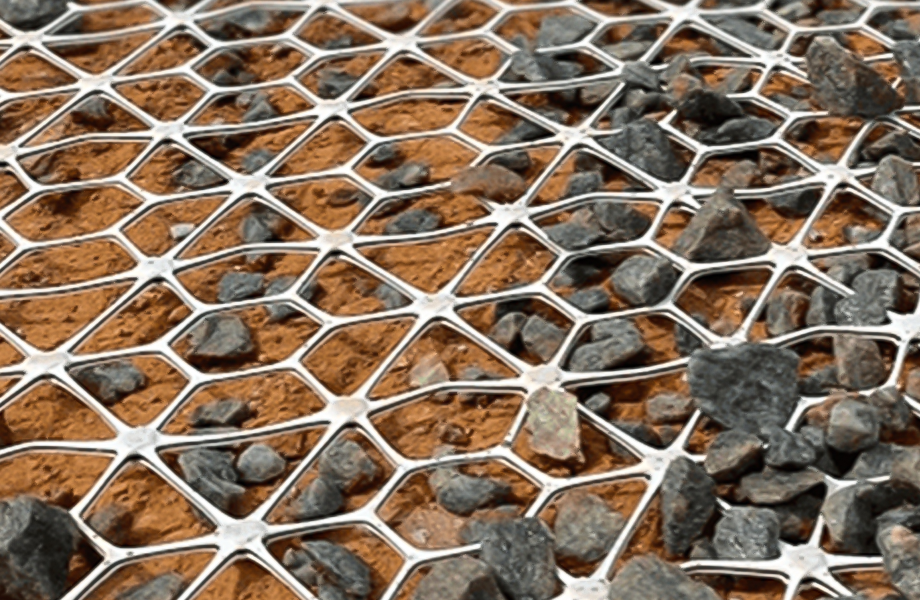

We will start from the top, the geogrid, to ensure we provide you with as much clarity and insights as possible. A geogrid is a geosynthetic material consisting of connected parallel sets of tensile ribs with apertures of sufficient size to allow strike-through of the surrounding soil, stone, or other geotechnical material (Koerner 1998). Geogrids provide reinforcement, stabilization, and even filtration with appropriately sized aggregate fills. Made from polymers such as polypropylene, polyethylene, or polyester, they are used widely in civil engineering applications. Over the years, significant advancements in geometry and performance have been made.

Learn More

Tensar InterAx geogrids are punched and oriented from a coextruded composite polymer sheet. The resulting structure consists of continuous and non-continuous ribs forming three aperture geometries (hexagon, trapezoid, and triangle) and an unimpeded suspended hexagon. The unique manufacturing process uses coextrusion to create a multi-layer product, allowing InterAx to accommodate aggregate nesting. The outer interactive layers conform to the aggregate shape and hold it in place. See how Tensar InterAx Geogrid can positively impact your Pavement Optimization, Heavy-Duty Roads, Crane Pads, and Working Surfaces.

Learn More

When it comes to soft soils, improving their strength, stability, and load-bearing capacity is critical. Tensar InterAx Geogrid's optimized geometry improves the geogrid-aggregate layer's performance by resisting the aggregate's radial displacement under load. Its unique open aperture shapes yield a broader range of sizes and open areas, allowing better compatibility with a more comprehensive range of aggregate qualities and gradations. Better performance means less aggregate is required to meet project requirements, saving costs, time, and carbon emissions.

Learn More

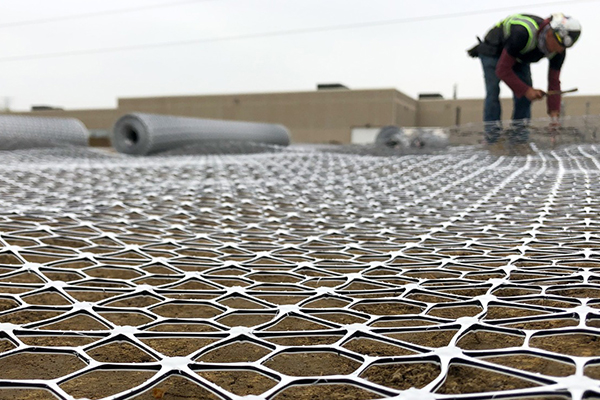

Chemical stabilization requires extra steps like soil testing for compatibility, specialized equipment, favorable weather conditions, and lengthy curing times. But these hurdles are avoided with Tensar InterAx geogrids. Geogrids ship efficiently and can be stored on a job site until the fill material arrives. It can then be quickly deployed just ahead of the trucks importing fill material to keep your installation team working ahead of schedule.

Tensar's innovative geogrid technology provides effective confinement of granular fill, resulting in a stiff mechanically stabilized layer (MSL) capable of controlling differential settlement and increasing bearing capacity. This efficiency results in less required aggregate to achieve the same performance—and less aggregate means less cost.

• Proven engineered alternative solutions to standard design practices

• Shorter construction schedules due to simplified construction and installation

• Cost savings resulting from lower-cost materials (foundations, platforms, and pavements)

The low initial cost of chemicals may be attractive. Still, other factors that go into proper installation, like confirming soil compatibility, curing time, and using specialized equipment, are often overlooked. There are also steep penalties for environmental statute violations and uncertainty surrounding its long-term performance. Here are just a few points to consider:

Soil Strength: The innovative design of Tensar InterAx geogrids optimizes the geogrid-aggregate interaction, improving the MSL performance and bolstering the strength and stability of soft soils.

Cost-Efficiency: Its ability to reduce the amount of aggregate required without compromising on performance results in significant cost savings. The reduced need for expensive traditional stabilization methods, such as Lime and Cement, further amplifies these savings.

Time-Saving: Compared to chemical stabilization, which demands soil testing, specialized equipment, favorable weather, and curing times, Tensar InterAx geogrids offer a quicker installation.

Extended Lifespan: Tensar's geogrid technology, by effectively confining granular fill, creates a stiff mechanically stabilized layer (MSL), which aids in controlling differential settlement. This means surfaces that are more resilient and last longer.

Eco-Friendly: With less aggregate required, there's a reduction in carbon emissions associated with mining and transporting these materials.

Versatility: Its unique manufacturing process and design, with various aperture geometries, make it compatible with a wide range of aggregate qualities and gradations.

Research-Backed: Tensar geogrids aren't just a novel innovation; they're backed by 50 years of research and validation, ensuring reliability and efficacy.

Simplified Construction: The geogrid's design and function streamline the construction and installation processes, leading to shorter construction schedules.

Settlement Control: With its superior strength and stiffness, the geogrid provides reliable settlement control, ensuring safer and more stable construction projects.

Innovation-Driven: Being a product of advanced engineering and manufacturing techniques, it represents the forefront of geogrid technology, positioning itself as a revolutionary product in the subgrade stabilization domain.

Learn More

The evolution of subgrade stabilization has witnessed a transformative shift with the introduction of Tensar InterAx Geogrids, offering a proven alternative to conventional stabilization methods such as Lime and Cement. As professionals seek efficient and cost-effective solutions, this geogrid technology emerges as a game-changer, heralded by five decades of rigorous research and validation.

Harnessing the power of Tensar InterAx geogrids offers a groundbreaking approach to fortifying soft soils, ensuring both stability and optimized load-bearing capacity. Learn how easy it is to install Tensar's InterAx geogrids, helping you create more resilient, longer-lasting surfaces for your subgrade stabilization projects.

Learn More