Understanding the Cost of Chemically Treated Subgrades Using Lime and Cement

One often-discussed topic in civil engineering is using chemical treatments for subgrade stabilization - specifically, the application of Chemical Stabilization by mixing on-site materials with Lime and Cement. These materials have proven effective in enhancing the load-bearing capacity of subgrades, thus preventing road failures and providing a sturdy foundation for construction and pavements.

While the technical merits are well-documented, the discussion on the cost implications of these treatments is often less comprehensive. This paper aims to bridge that gap by presenting a detailed overview of the costs of using Lime and Cement for Chemical Subgrade Stabilization.

Subgrade stabilization refers to improving the strength, stability, and load-bearing capacity of the subgrade, which is the natural soil or existing ground on which a roadway or other construction project is built. Subgrade stabilization techniques are employed to enhance the properties of the subgrade, making it better able to support the weight and traffic loads imposed by the pavement structure.

In some cases, the natural soil may not have the strength, stability, or durability to serve as a reliable subgrade. It may be too soft, permeable, prone to swelling and shrinking with moisture changes, or sensitive to frost. These are instances where subgrade stabilization is needed. Subgrade stabilization involves treating the soil with certain materials or methods to enhance its physical properties. This could include increasing its bearing capacity, reducing its permeability, or making it more resistant to weathering and wear.

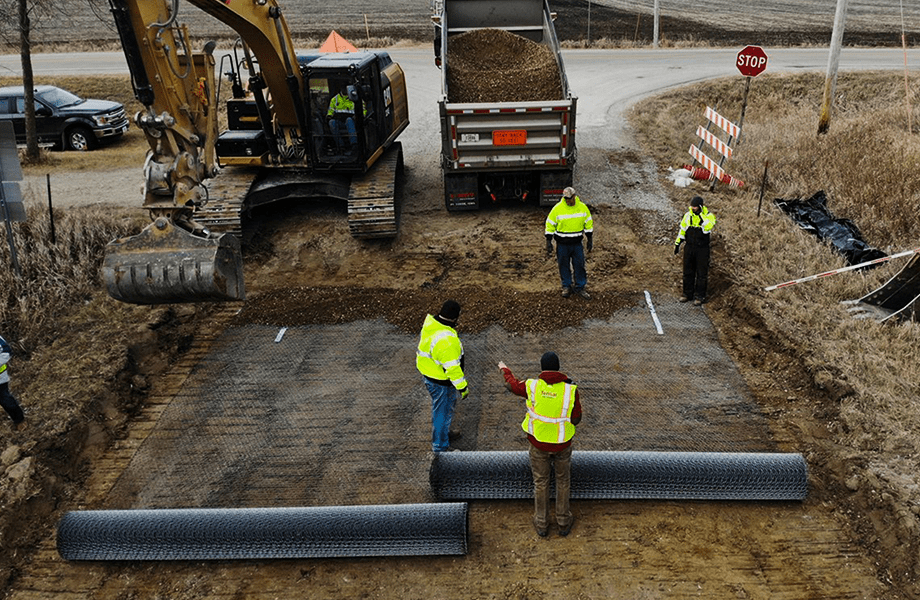

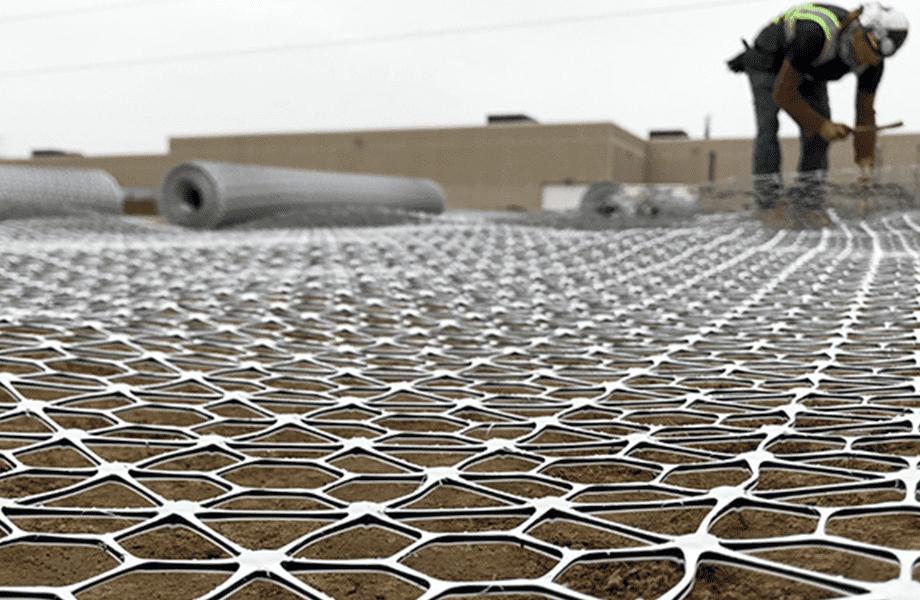

Several methods are available for subgrade stabilization, but Chemical Stabilization is the most commonly used method that involves the incorporation of additives like lime or cement into the soil. Stabilizing the subgrade forms a more robust and more durable foundation for the pavement structure, which can reduce the thickness and cost of the pavement layers above it, speed up the construction process, and improve the performance and lifespan of the future roadway or structure. Beyond stabilizing subgrades with lime and cement, other additives, such as fly ash or polymer-based agents, modify the soil chemically. Adding a layer of aggregate base or subbase above the subgrade can also provide stabilization. These granular materials distribute loads over a larger area, improving the load-bearing capacity of the pavement structure and reducing stress on the subgrade. Mechanical stabilization techniques involve incorporating geogrids, geotextiles or geocells into the subgrade. These materials act as reinforcing elements, distributing the applied loads and reducing the potential for soil deformation. They can also improve the drainage characteristics of the subgrade.

Lime treatment involves adding hydrated Lime to the soil. The Lime reacts with the clay particles in the soil, triggering a pozzolanic reaction that permanently alters the properties of the soil, increasing its load-bearing capacity and reducing its plasticity and swell potential.

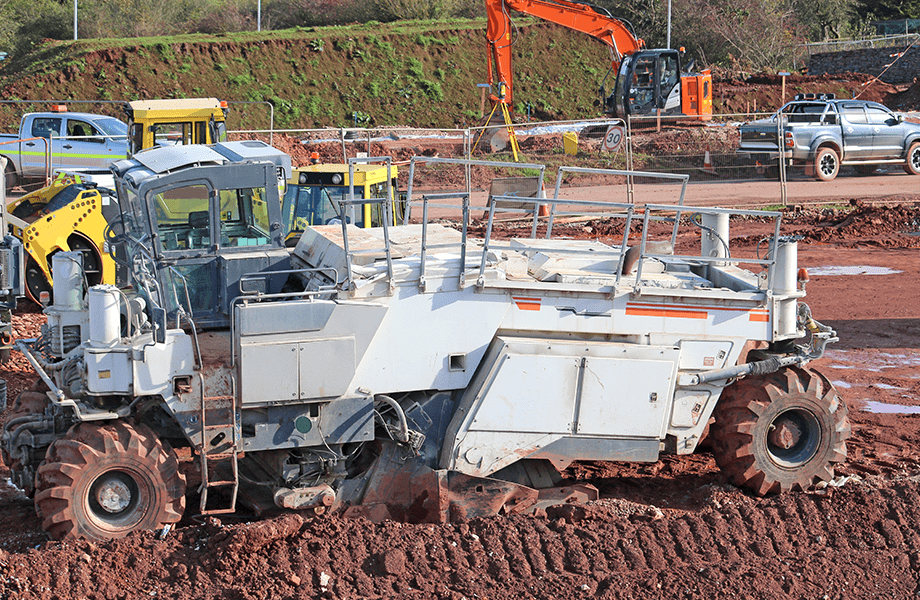

Cement treatment involves the addition of Portland cement to the soil. The cement reacts with the soil and water to form a hardened, cemented mass that significantly improves the load-bearing capacity of the subgrade.

The pozzolanic reaction between lime and soil particles, especially with clay, enhances soil strength and durability. Lime stabilization decreases the soil's propensity to swell when wet and shrink when dry, improving stability. It improves the soil's load-bearing capacity, reducing the need for thick pavement structures and resulting in long-term cost savings.

Cement-stabilized soil is very durable and resistant to weathering and wear, which reduces long-term maintenance costs. Cement creates a moisture-resistant layer, reducing the risk of water damage and enhancing pavement life.

Chemically treating subgrades using lime and cement entails several cost components, such as material costs, labor costs, equipment costs, and indirect costs that cover project management and quality control.

Material costs depend heavily on the local availability of lime and cement, the distance between the project site and the source, and market fluctuations. The specific soil properties and the desired stabilization level also determine the quantity of material required. On the other hand, labor costs hinge on the local wage rates and the complexity of the application. Lime treatment often necessitates a more extended curing period than cement treatment, escalating labor costs.

Equipping for the task is another vital facet to consider. Specialized machinery, including soil spreaders and mixers, is needed for lime and cement treatment. Procuring this equipment through rental or purchase can significantly add to the project costs. Beyond these direct costs, project management and quality control constitute indirect costs. These encompass soil testing, supervision, compliance with environmental regulations, and any necessary remediation measures.

While Lime may seem relatively inexpensive, the overall cost of lime soil stabilization can escalate quickly, depending on several factors. The local availability of Lime can significantly impact its price, and the specialized equipment and expertise needed for proper integration into the soil can also add to the overall expense.

Despite cement's effectiveness in soil stabilization, its relatively high cost can make it a prohibitive choice for many projects. Cement's price, subject to market conditions and local availability, generally exceeds that of alternatives like Lime. Furthermore, incorporating cement into soil demands specialized equipment and higher energy input, adding to the financial burden. Consequently, the overall cost of cement for soil stabilization can escalate quickly, becoming a significant consideration in project budgeting.

The environmental impact of both lime and cement production is considerable. These processes are energy-intensive and result in substantial greenhouse gas emissions, thereby contributing to global climate change. Moreover, the raw material extraction for cement production can lead to habitat destruction and biodiversity loss. The procedures are also sensitive to weather conditions. Wet or cold weather can hamper curing, potentially disrupting the project timeline and cost. In arid climates, maintaining the necessary moisture content for apt curing can be a challenge.

Geosynthetics have a rich history spanning several decades, and their development has been marked by continuous innovation and improvements. The history of geosynthetics dates back to the 1950s when the first patent for a geotextile was filed. Geosynthetics gained recognition and became widely adopted in the 1960s and 1970s for applications such as soil stabilization, erosion control, and drainage systems. Over time, geosynthetics have undergone technological advancements and innovations, leading to improved materials and design standards. The 1980s saw the development of geogrids, which offered enhanced reinforcement properties for soil stabilization and load distribution.Today, they are widely recognized as effective alternatives to lime and cement treatment for chemical stabilization, offering versatility, cost-effectiveness, and sustainability in the mechanical reinforcement of subgrades.

In recent years, an innovative solution, InterAx Geogrid, developed by Tensar, has emerged as a viable alternative to traditional chemical stabilization methods like Lime and cement treatment. Driven by data, InterAx Geogrids are designed with unique geometric apertures that create better interlock with the aggregate above and below the geogrid, providing improved aggregate confinement and load distribution. These features make InterAx Geogrids particularly effective in the roadway, parking lot, and laydown yard applications, enhancing the bearing capacity and reducing the deformation under load.

In conclusion, this paper underscores the critical role of chemical treatments, specifically Lime and Cement, in subgrade stabilization for construction, as they enhance the load-bearing capacity of subgrades and provide a robust foundation for building. However, balancing their effectiveness with cost and environmental considerations is crucial. While Lime and Cement treatment can often seem cost-effective initially, long-term expenses and environmental impacts call for a more holistic assessment. The emergence of alternatives like the InterAx Geogrid by Tensar offers promising possibilities for sustainable and cost-effective solutions. Therefore, continued research and innovation in civil engineering are imperative for advancing subgrade stabilization methods that marry effectiveness, economic viability, and environmental responsibility.

Learn More